Hotline:

18917685339

18917685337

I. Working process and principle

1. The grinding fluid is injected into the TCF-300 magnetic separator by the lift pump, during which a large number of ferromagnetic impurities are separated

2. The grinding fluid processed by the strong magnetic separator enters into the arc plate filter, which is designed for automatic control

3. When more and more sludge is deposited on the filter paper, the liquid level rises, triggering the float ball to approach the paper switch, and the filter mechanical machine starts to replace the filter paper and take away the deposited sludge. At this time, the liquid level drops and the motor stops running

Two, technical parameters

1. Automatic tape filter

Power: 90 w

Filter paper specification: 700mm*100m

2. Magnetic separator

Model: TCF-300 Power: 90W

Processing capacity: 300L/min

3. Instructions for use

This paper tape filter is suitable for the filtration of aqueous solution and emulsion

The coolant filtration and purification process is that the machine coolant flows into the magnetic separator through the pipe first, and the first stage filtration is realized under the action of the magnetic separator. Then the coolant flows into the paper tape filter to realize the second stage filtration under the action of the filter paper; After two times of purification, the pure coolant can be stored in the water tank or directly into the machine tool equipment, and so on.

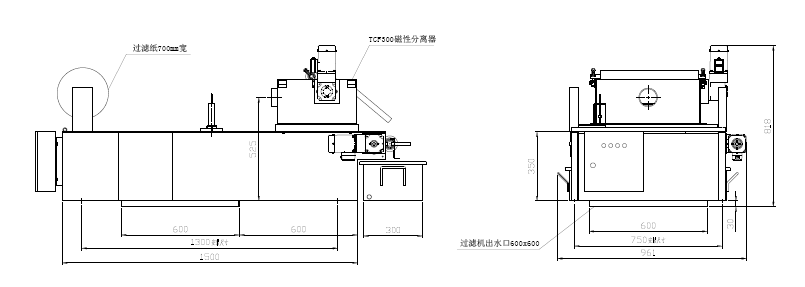

外形尺寸图