Hotline:

18917685339

18917685337

Technical parameters:

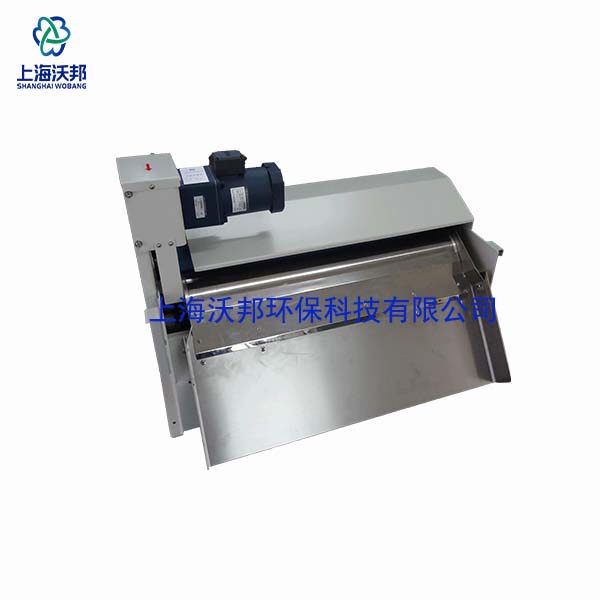

Model: QCF - 600

Voltage: three-phase 380V

Motor power: 200W

Motor speed: 1400RPM

Dimensions: 1080*480*550mm

Traffic: 200 l/MIN

Product Introduction:

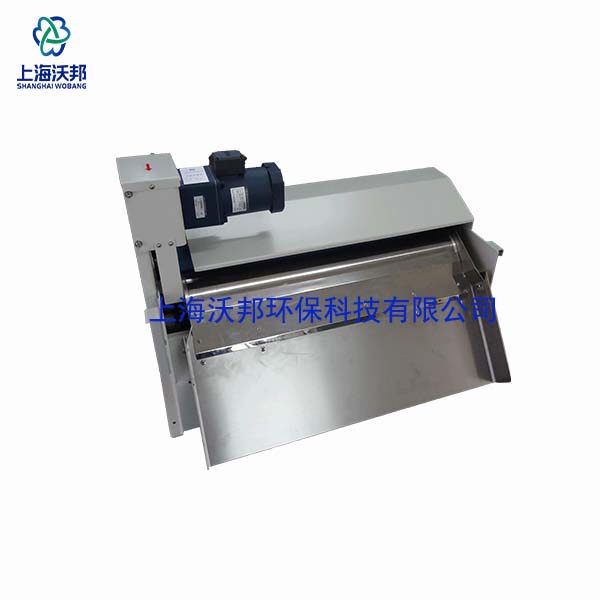

A, use

This product is used to purify coolant of metal cutting machine tools (including cutting grease and emulsified oil). The ferromagnetic impurities in the coolant are separated by the strong suction of the magnetic hub of the magnetic separator. Suitable for grinding machine, precision grinding machine and other metal cutting machine tools.

Second, the characteristics of

1, this product uses strong magnetic hub, and with the form of belt slag to make the impurities can be smoothly discharged.

2, the use of soft cots extrusion discharge of dirt, will not bring out the coolant, so that the discharge of ferromagnetic powder impurities to keep dry, to ensure a clean working environment.

Three, the working principle

When the coolant enters the box body from the entrance and flows through the arc surface channel under the magnetic hub, the ferromagnetic impurities in the liquid are magnetized on the conveyor belt around the magnetic hub, and the cleaning liquid flows out of the outlet. Magnetic hub constantly rotating, cots extrusion impurities in the residual liquid, scraper scraping away adsorbent, complete the automatic separation of impurities.

Iv. Precautions for use

1. Select the type according to the liquid flow of the machine tool;

2, reducer and magnetic hub through the chain transmission, the tightness is adjustable;

3. If the discharged impurity water is too much, the extrusion pressure of the rubber roller can be adjusted, and the size of the spring force can be realized.

4. The tightness of the scraper is adjustable and can be removed when cleaning.

5, regular maintenance and maintenance of the product, timely cleaning cots and magnetic hub surface attachments.